High-Quality Organic Coffee Powder Drip Coffee Packaging Machine for Thai Coffee

The organic coffee powder drip coffee packaging machine is a cutting-edge solution designed to meet the growing demand for premium, hygienic packaging in the specialty coffee industry, particularly for Thai coffee producers. This machine combines advanced automation with food-grade materials to ensure consistent, high-quality packaging of organic coffee powder, tea, and other small granule products

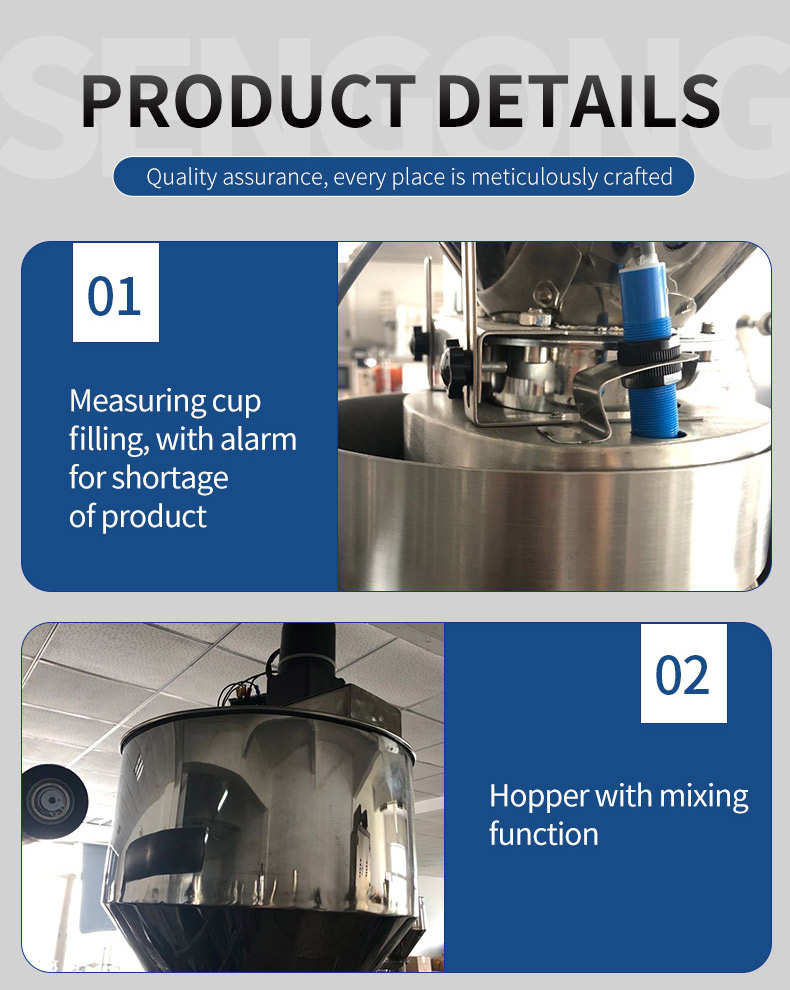

Key Features and Technical Specifications

Precision and Efficiency:

Filling range: 5–10g (adjustable based on product density)

Packaging speed: 20–40 bags per minute, ideal for high-volume production

Step motor-controlled outer bag sealing ensures accurate bag length positioning, minimizing material waste

Material and Safety Standards:

All parts in direct contact with coffee powder are made of SUS304 stainless steel, meeting international food hygiene standards

Optional nitrogen filling system preserves freshness and extends shelf life

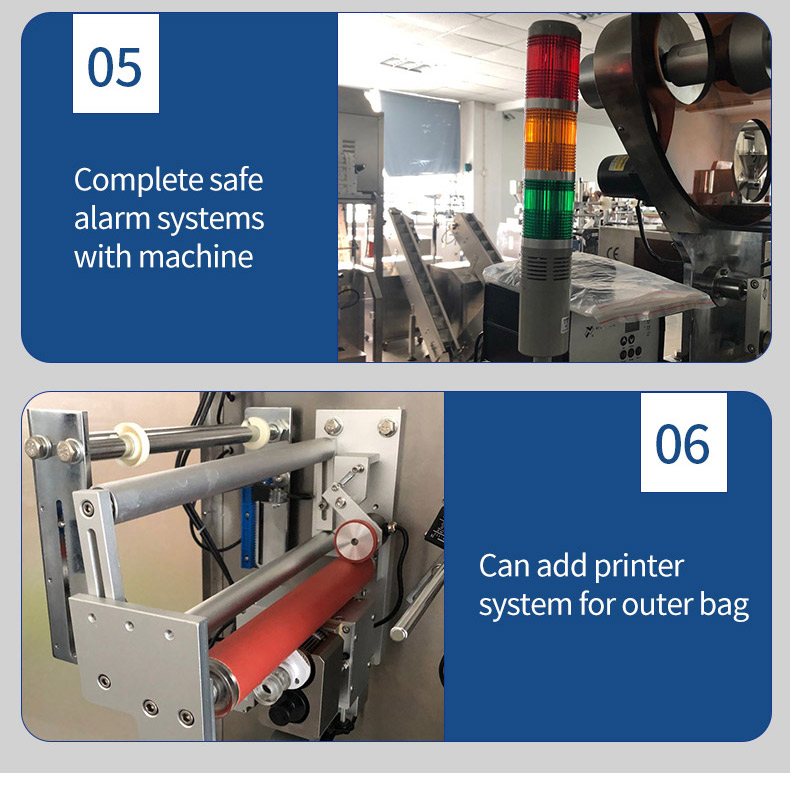

Safety features include automatic shutdown for abnormal air pressure or heater disconnection

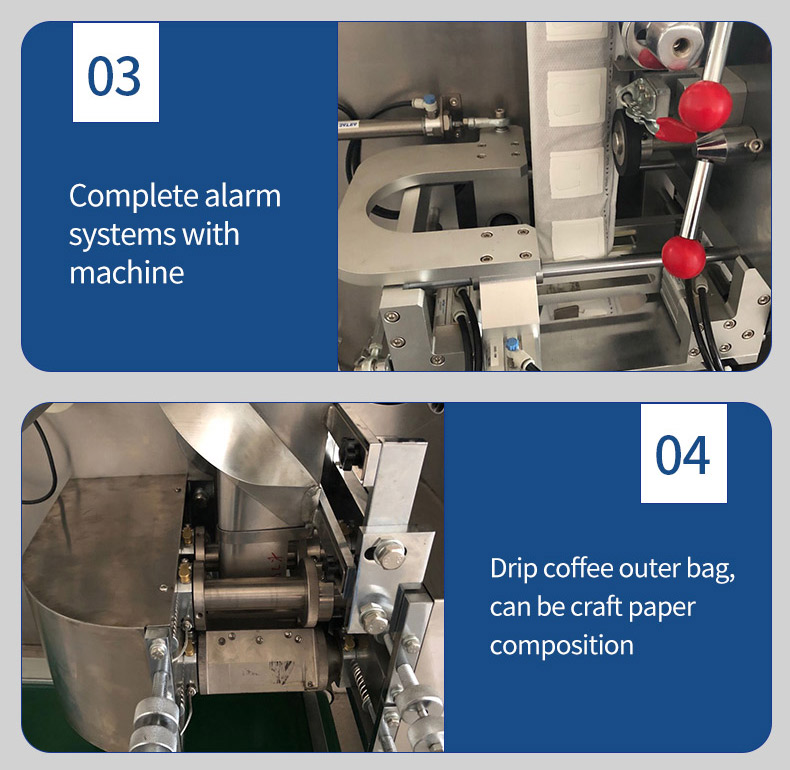

Customization and Flexibility:

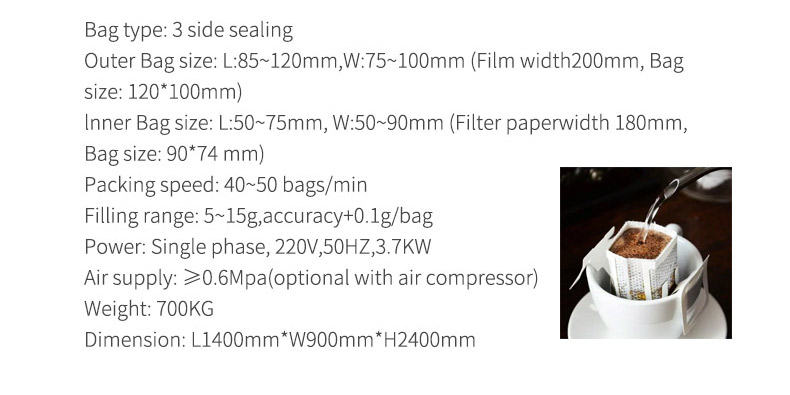

Supports inner and outer bag packaging for drip coffee pods, tea bags, and specialty sachets

Adjustable bag sizes: outer bag (max. 100mm × 120mm), drip bag (max. 90mm × 70mm)

Optional accessories: date printers, easy-tear devices, and flat-cut tools for branding and user convenience

User-Friendly Design:

PLC control system with a multifunctional touchscreen for easy parameter adjustment

PID temperature controller ensures precise heat sealing for diverse film materials (e.g., PET/AL/PE, NY/PE)

Step-by-step video tutorials and detailed manuals simplify operation and troubleshooting

Why Choose This Machine for Thai Coffee?

Thai coffee, known for its unique flavor profile and cultural significance, requires packaging that maintains freshness and appeals to global markets. This machine addresses these needs by:

Preserving organic coffee’s aroma and quality through nitrogen flushing and airtight sealing

Offering customizable bag designs to highlight Thai branding or cultural motifs

Supporting small-batch production for specialty roasters while maintaining scalability

Factory-Supplied Solutions and Support

Jike Bee Machinery and other leading suppliers provide end-to-end solutions, including:

Customized packaging line designs based on client requirements

Rigorous quality inspections and international shipping in wooden crates

technical support and overseas engineer services for seamless machine integration

Conclusion

The organic coffee powder drip coffee packaging machine is a versatile, reliable choice for Thai coffee producers aiming to enhance product quality and market competitiveness. With its advanced automation, food-safe materials, and customizable features, this machine ensures efficient, hygienic packaging that meets both local and export standards. Explore factory-direct options and request a free operation video to learn more!

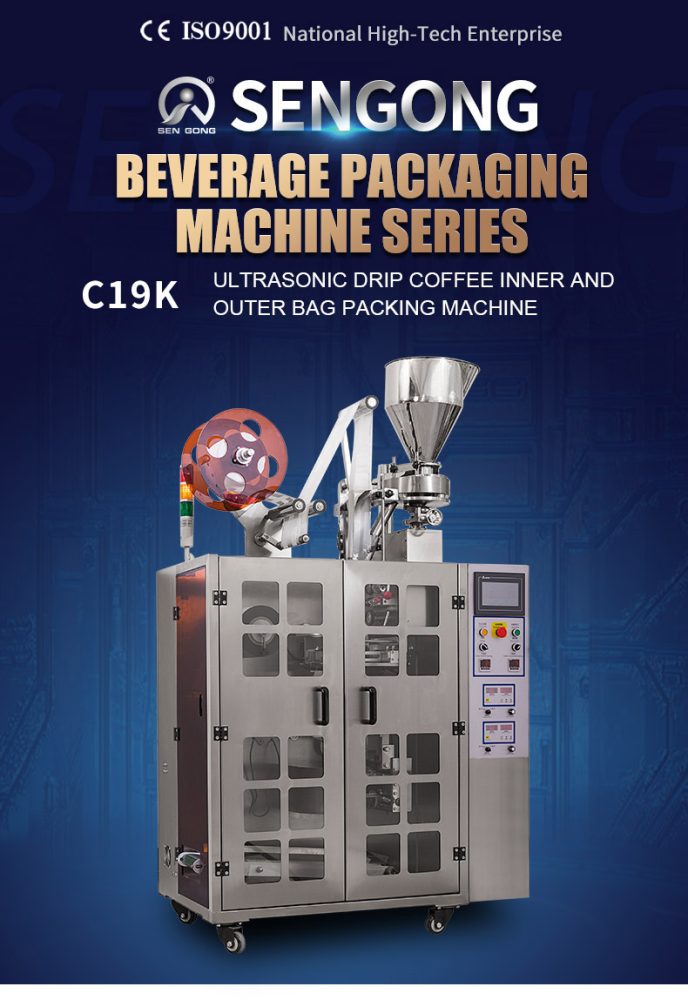

Type: Drip Coffee Packing Machine Series

Product model: C19K

Product name: Ultrasonic Drip Coffee Inner and Outer Bag Packing MachineOuter bag sealing controlled by the servo motor,

Purpose: bag length positioning is accurate and stable.

Feature: Outer bag sealing controlled by the servo motor , bag length positioning isaccurate and stable.

Adopts PID temperature controller for more accurate temperature adjustment.Adopts PLC control system, human-machine interface, it is very easy to operate.

All parts in direct contact with products are made of sUS304 stainless steel,ensuring reliable products output conforming to food sanitary standards.Some parts of the cylinder are imported, ensuring the accuracy and stabilityof performance.

Optional devices: flat cut device, date printer, easy tear device, etc.

Packing Material: Paper/Plastic,Plastic/Aluminum/Plastic,PaperlAluminum/Plastic,Drip coffee filter paper

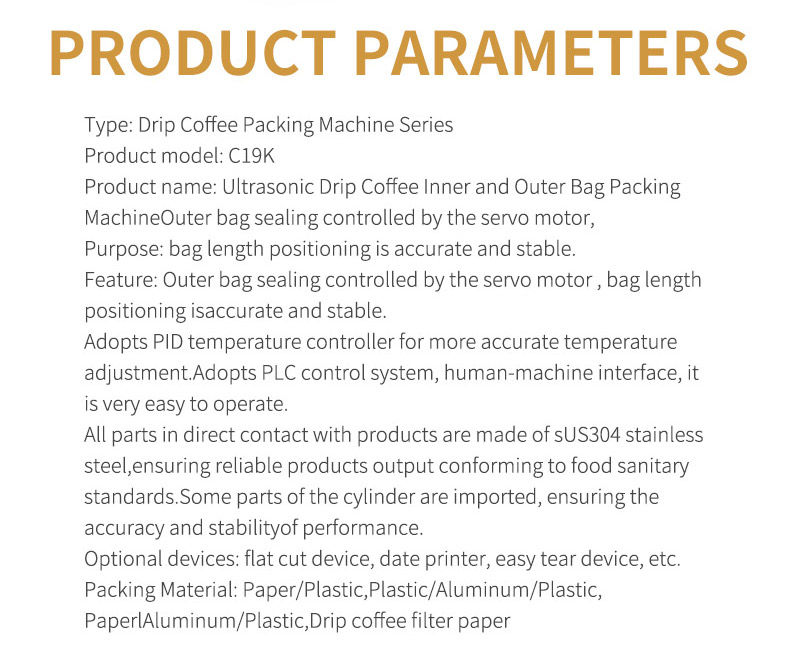

Bag type: 3 side sealing

Outer Bag size: L:85~120mm,W:75~100mm (Film width200mm, Bag size: 120*100mm)

lnner Bag size: L:50~75mm, W:50~90mm (Filter paperwidth 180mm, Bag size: 90*74 mm)

Packing speed: 40~50 bags/min

Filling range: 5~15g,accuracy+0.1g/bag

Power: Single phase, 220V,50HZ,3.7KW

Air supply: ≥0.6Mpa(optional with air compressor)

Weight: 700KG

Dimension: L1400mm*W900mm*H2400mm