This automatic drip coffee bag packaging machine is specially designed to cater to the packaging needs of Bolivia’s premium drip coffee, a product celebrated for its unique flavor profile, organic origins, and high market value. The machine integrates inner and outer bag forming in a single step, eliminating manual handling of coffee beans/grounds and ensuring a hygienic, efficient production process—critical for preserving the purity of Bolivia’s coffee.

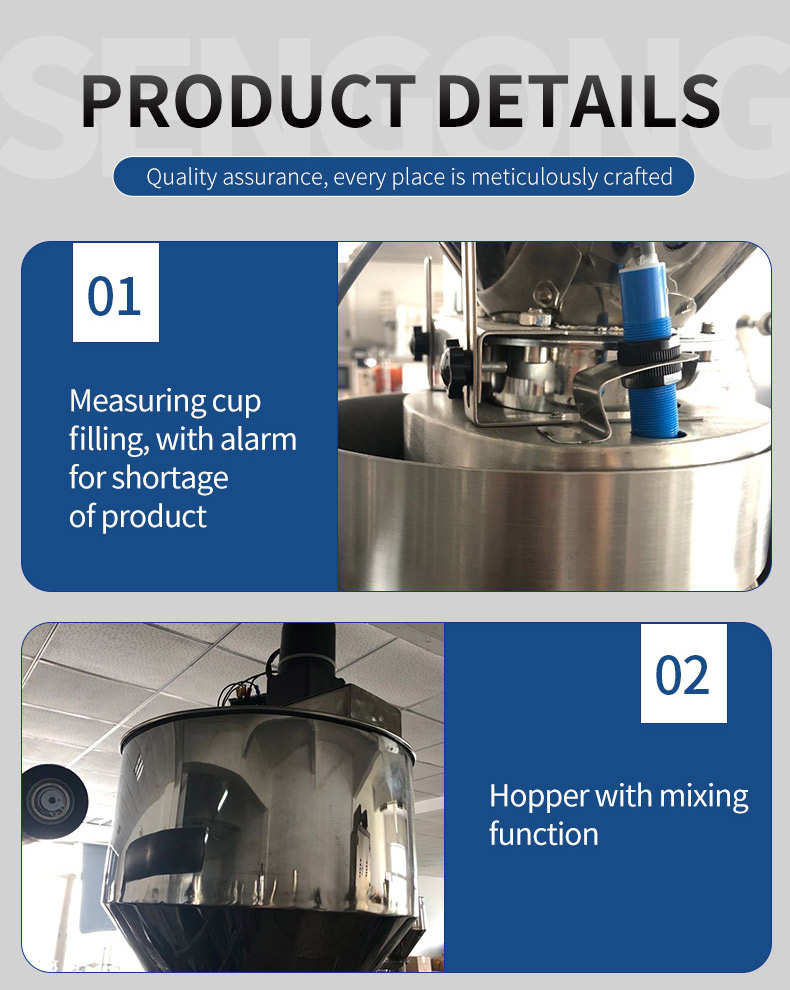

Constructed with food-grade SUS304 stainless steel, the machine meets strict sanitary standards, preventing contamination and maintaining the coffee’s natural quality. Key features include:

PID temperature control for precise sealing, avoiding heat damage to the coffee’s aroma.

PLC control system with a user-friendly touchscreen, enabling easy adjustment of bag size, filling quantity, and speed.

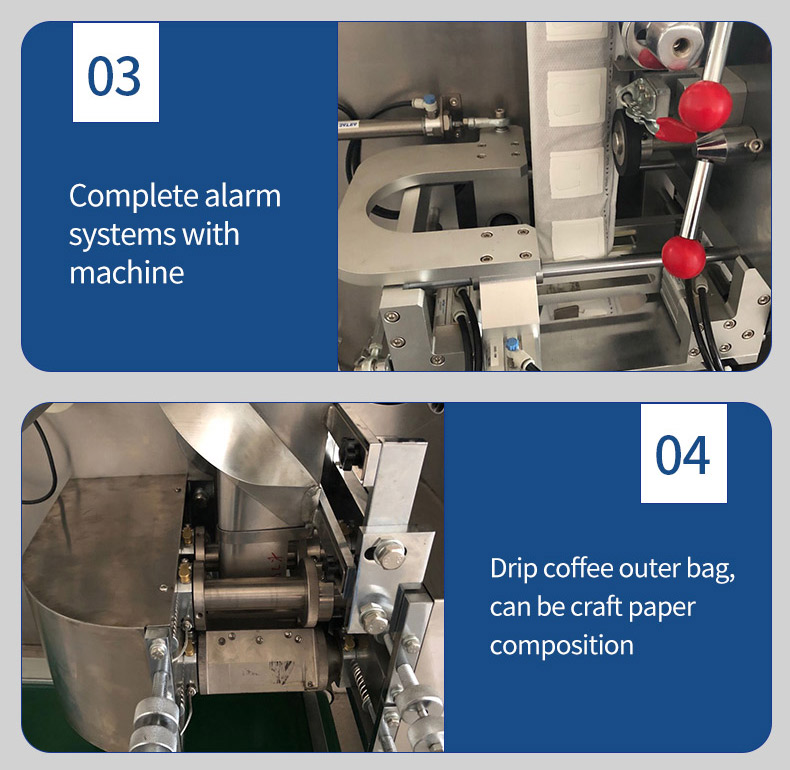

Ultrasonic sealing technology, which creates a tight, airtight seal without generating excess heat, preserving the coffee’s freshness.

Optional nitrogen flushing device, which displaces oxygen in the bag to extend shelf life—essential for retaining the rich, bold flavor of Bolivia’s drip coffee.

With a packing capacity of 5–15 grams per bag and a speed of 30–45 bags per minute, this machine is ideal for small to medium-sized coffee producers in Bolivia. It balances efficiency with precision, allowing businesses to scale production while maintaining the unique characteristics that define Bolivia’s drip coffee.

Whether for local markets or export, this packaging machine helps Bolivian coffee brands showcase their premium products in attractive, functional packaging—ensuring that every cup of drip coffee delivers the authentic taste of Bolivia’s coffee-growing regions.

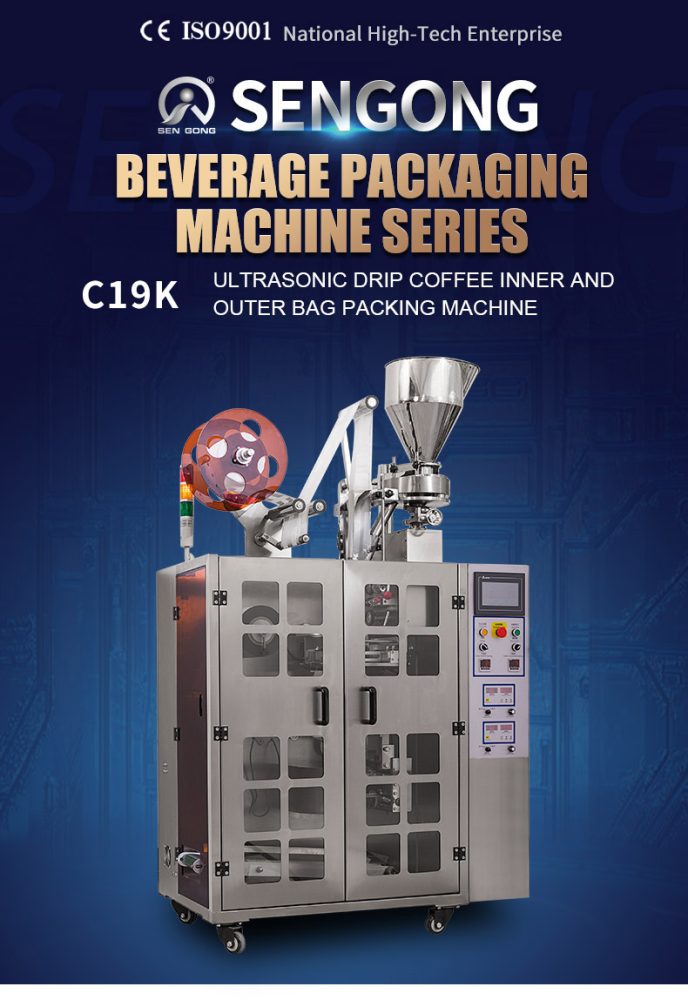

Type: Drip Coffee Packing Machine Series

Product model: C19K

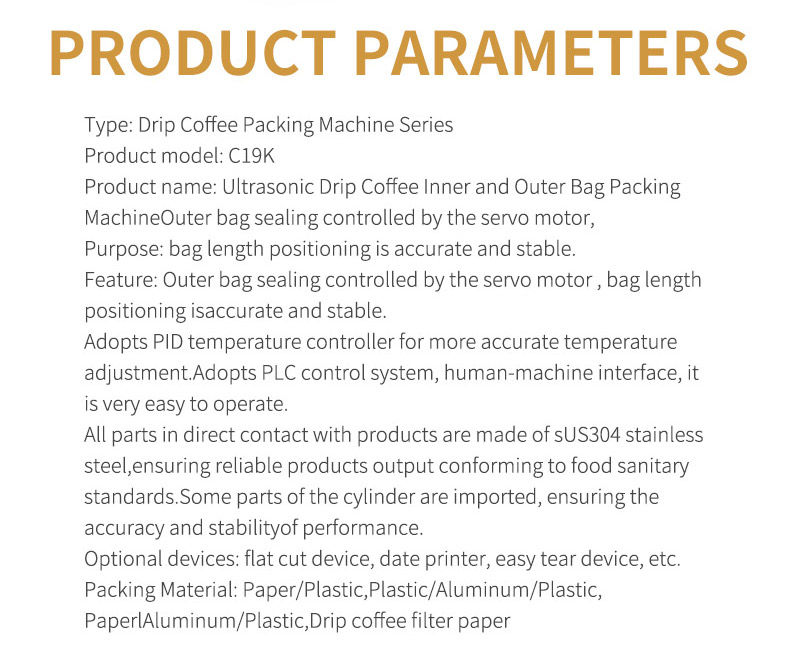

Product name: Ultrasonic Drip Coffee Inner and Outer Bag Packing MachineOuter bag sealing controlled by the servo motor,

Purpose: bag length positioning is accurate and stable.

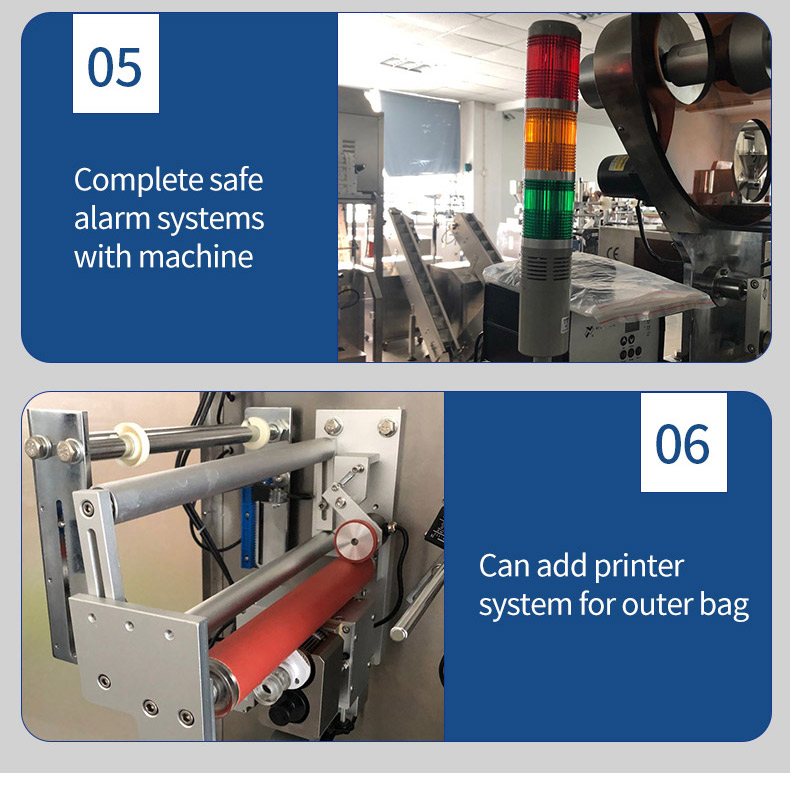

Feature: Outer bag sealing controlled by the servo motor , bag length positioning isaccurate and stable.

Adopts PID temperature controller for more accurate temperature adjustment.Adopts PLC control system, human-machine interface, it is very easy to operate.

All parts in direct contact with products are made of sUS304 stainless steel,ensuring reliable products output conforming to food sanitary standards.Some parts of the cylinder are imported, ensuring the accuracy and stabilityof performance.

Optional devices: flat cut device, date printer, easy tear device, etc.

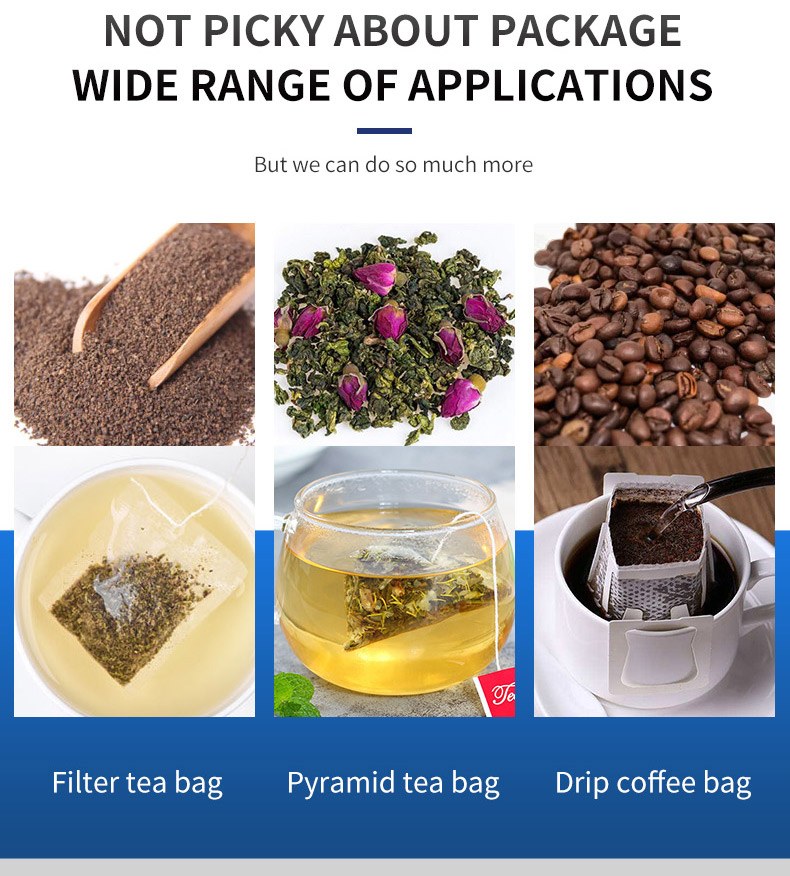

Packing Material: Paper/Plastic,Plastic/Aluminum/Plastic,PaperlAluminum/Plastic,Drip coffee filter paper

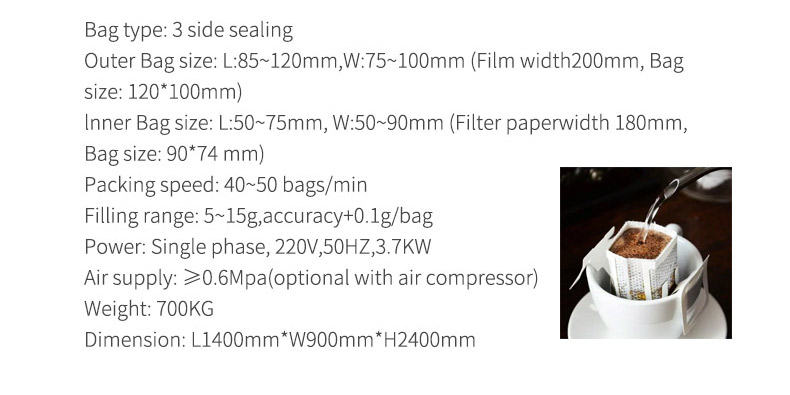

Bag type: 3 side sealing

Outer Bag size: L:85~120mm,W:75~100mm (Film width200mm, Bag size: 120*100mm)

lnner Bag size: L:50~75mm, W:50~90mm (Filter paperwidth 180mm, Bag size: 90*74 mm)

Packing speed: 40~50 bags/min

Filling range: 5~15g,accuracy+0.1g/bag

Power: Single phase, 220V,50HZ,3.7KW

Air supply: ≥0.6Mpa(optional with air compressor)

Weight: 700KG

Dimension: L1400mm*W900mm*H2400mm