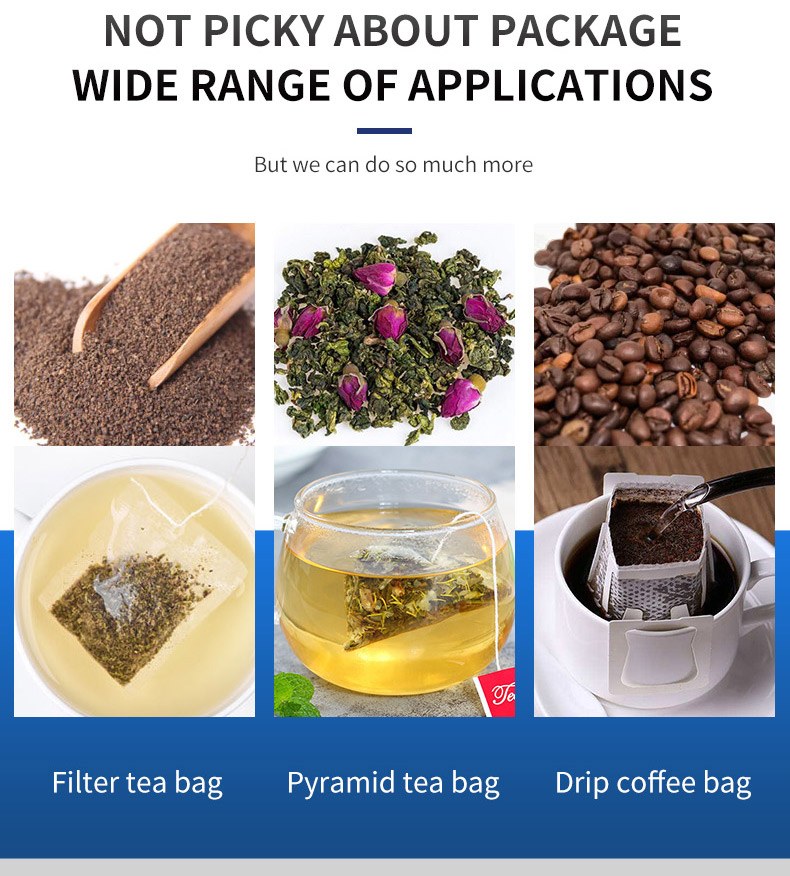

The ultrasonic drip coffee bag packaging machine is designed for high-efficiency packaging of Moroccan coffee, utilizing advanced ultrasonic sealing technology to ensure airtight and hygienic packaging . This machine supports both inner and outer bag packaging, ideal for preserving the aroma and freshness of Moroccan coffee. Key features include:

Ultrasonic Sealing: Non-thermal sealing prevents coffee oxidation and maintains flavor integrity, suitable for heat-sensitive materials like filter paper, non-woven fabric, and laminated films.

Automated Nitrogen Flushing: An optional nitrogen injection system displaces oxygen in the outer bag, extending shelf life and preserving coffee quality.

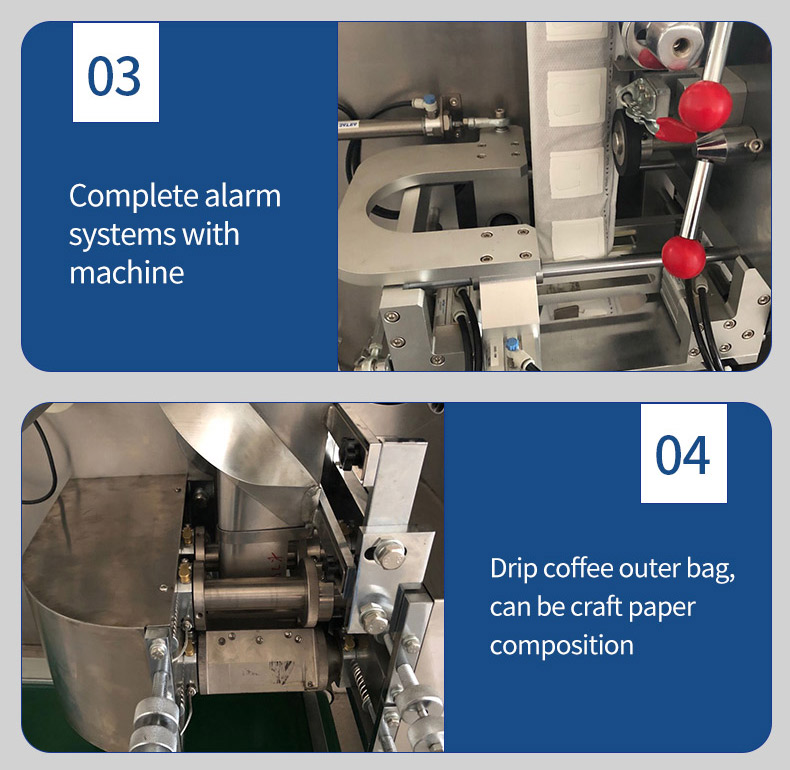

Multi-Layer Packaging: Handles inner drip bags (e.g., non-woven hanging-ear filters) and outer bags (plastic/aluminum composites) simultaneously, with adjustable sizes for Moroccan-style drip bags (e.g., 90×75mm inner, 120×100mm outer) .

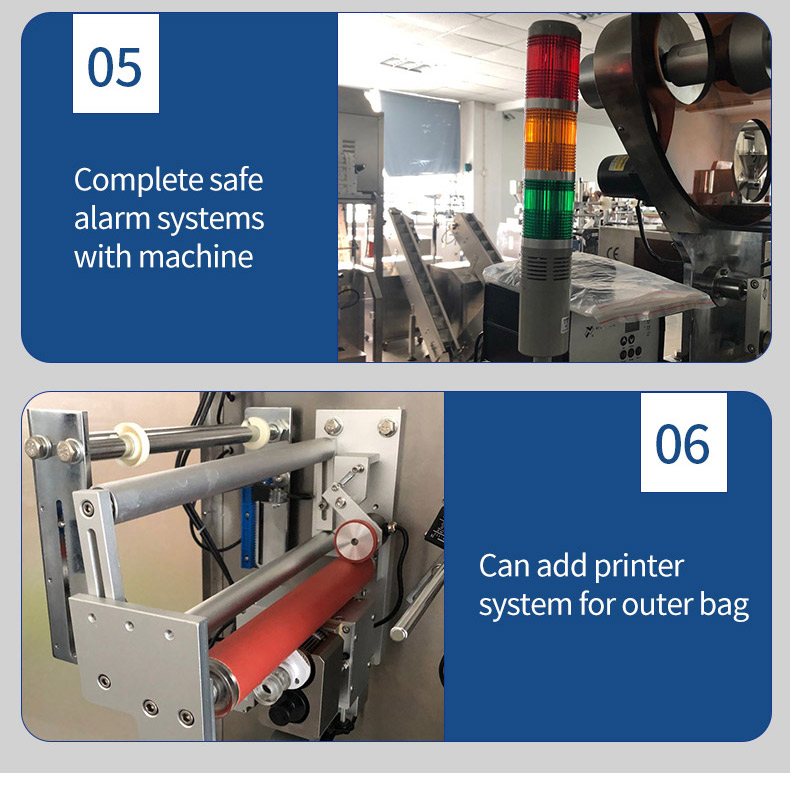

PLC Control & Touchscreen Interface: Ensures precise temperature regulation (PID controller), servo-driven film feeding, and customizable parameters for bag length, sealing time, and production speed (30–60 bags/min) .

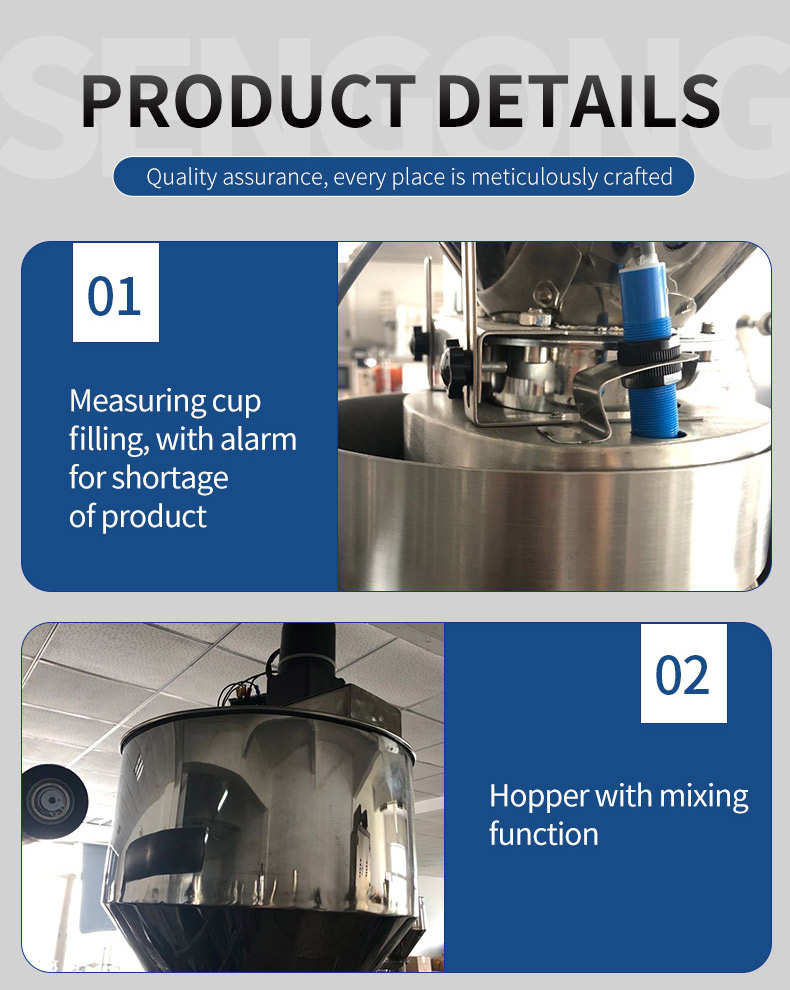

Food-Grade Construction: SUS304 stainless steel components and imported pneumatic parts comply with international hygiene standards, critical for food-grade applications 24.

This machine is compatible with Moroccan coffee’s granular or powdered form, offering flexibility for small-batch artisanal production or high-volume commercial use. Additional features include date coding, tear-notch options, and easy integration with existing production lines.

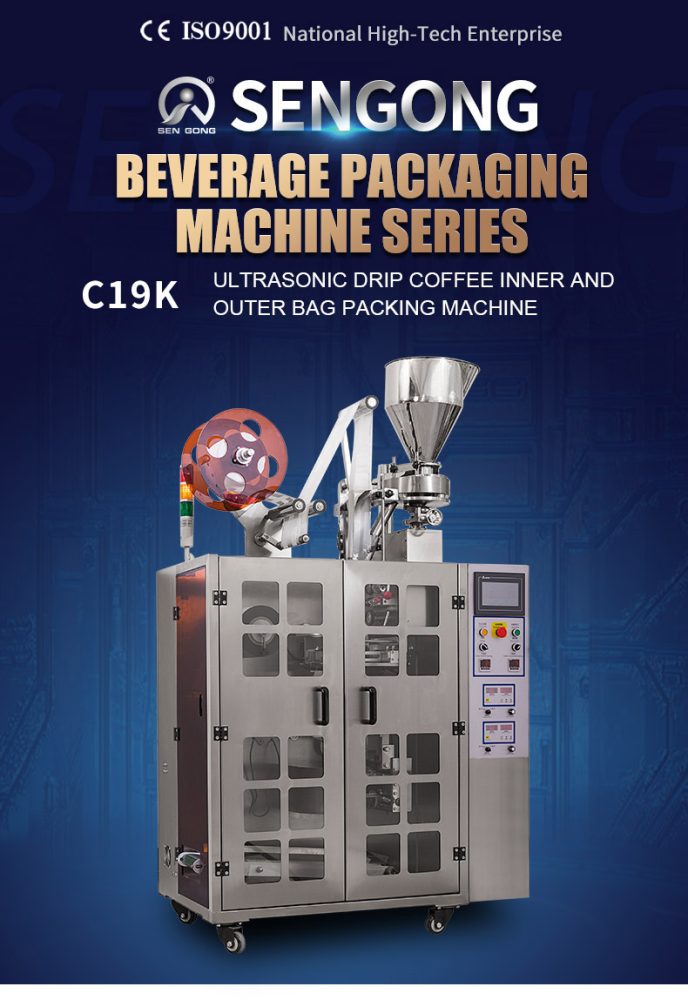

Type: Drip Coffee Packing Machine Series

Product model: C19K

Product name: Ultrasonic Drip Coffee Inner and Outer Bag Packing MachineOuter bag sealing controlled by the servo motor,

Purpose: bag length positioning is accurate and stable.

Feature: Outer bag sealing controlled by the servo motor , bag length positioning isaccurate and stable.

Adopts PID temperature controller for more accurate temperature adjustment.Adopts PLC control system, human-machine interface, it is very easy to operate.

All parts in direct contact with products are made of sUS304 stainless steel,ensuring reliable products output conforming to food sanitary standards.Some parts of the cylinder are imported, ensuring the accuracy and stabilityof performance.

Optional devices: flat cut device, date printer, easy tear device, etc.

Packing Material: Paper/Plastic,Plastic/Aluminum/Plastic,PaperlAluminum/Plastic,Drip coffee filter paper

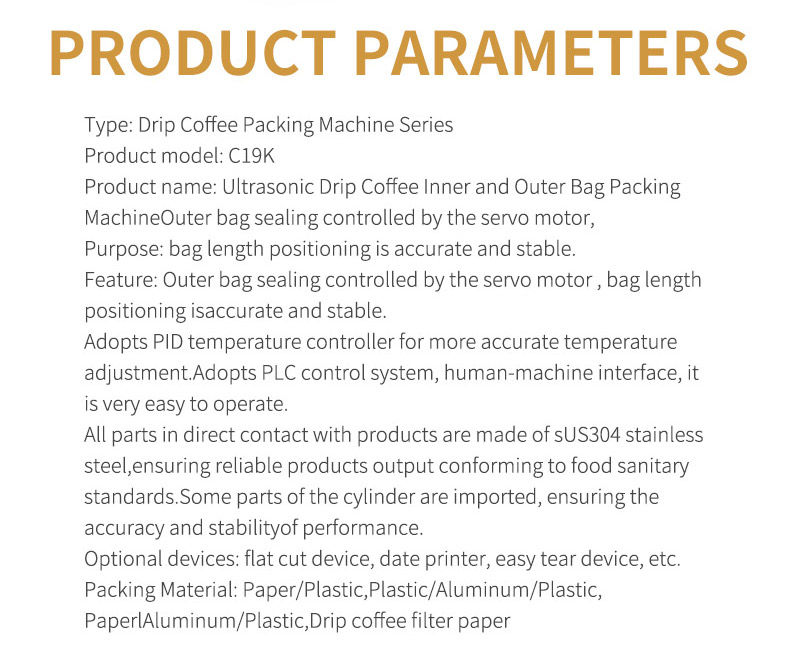

Bag type: 3 side sealing

Outer Bag size: L:85~120mm,W:75~100mm (Film width200mm, Bag size: 120*100mm)

lnner Bag size: L:50~75mm, W:50~90mm (Filter paperwidth 180mm, Bag size: 90*74 mm)

Packing speed: 40~50 bags/min

Filling range: 5~15g,accuracy+0.1g/bag

Power: Single phase, 220V,50HZ,3.7KW

Air supply: ≥0.6Mpa(optional with air compressor)

Weight: 700KG

Dimension: L1400mm*W900mm*H2400mm